Sponsor a Student Research Project

Student Research Projects

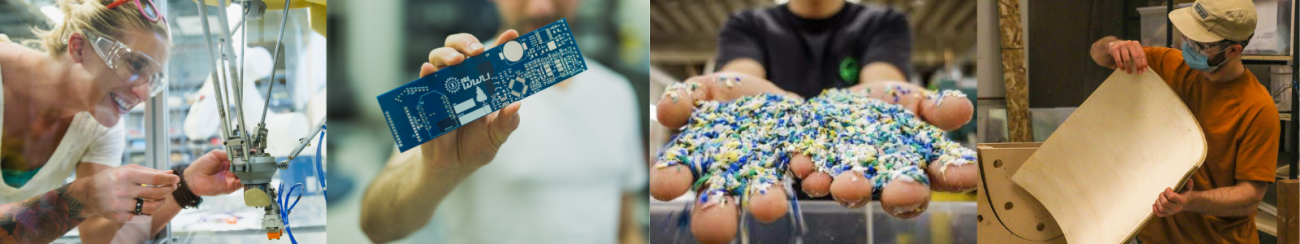

Over the course of their senior year, students develop a senior project, often with an industry sponsor. These industry sponsored projects contribute to the hands-on engineering education offered at Western.

Students spend the first two quarters in the proposal and planning phases of the project, with the implementation phase beginning in spring quarter. Industry partners are just as invested as the student when it comes to the project's success.

It is crucial that we offer challenging and suitable projects to our students to give them more experience in project management, technical writing, synthesizing different concepts from their education, working as a team and individually, and communicating with suppliers and customers.

Become an Industry Sponsor

If you would like to get involved, consider sponsoring a student senior project in our Manufacturing Engineering or Polymer Material Engineering programs.

Manufacturing Engineering

Manufacturing Engineering seniors design and implement a project of their choosing. Students present their projects to their peers, faculty, and project sponsors at the end of spring quarter. Projects are often in collaboration with companies in industry. A successful Engineering program combines what is learned in the classroom and experienced in the lab with real-world manufacturing and design problems.

It is essential to sponsor projects that focus on one or more of the four pillars of manufacturing engineering body of knowledge defined by the Society of Manufacturing Engineers (SME). These pillars are materials and manufacturing processes, product tooling and assembly engineering, manufacturing systems and operations, and manufacturing competitiveness.

Sponsor an MFGE Project

Polymer Materials Engineering

Polymer Materials Engineering seniors are presented with numerous projects to choose from (that vary depending on the projects offered by industry). The majority of the PME projects are: process design, process investigation, product design, machine design, software applications, material investigation, or tool design.

Each project has a specific problem that needs to be solved and must contain a significant design component. Students will then define the problem, develop specifications, investigate and present multiple solutions, select the best solution and develop an implementation plan including timeline and budget. During this time, all projects start in the Fall and are implemented in the Spring.

Sponsor a PME Project

Contact:

Nicole Hoekstra, Professor

Polymer Materials Engineering

hoekstra@wwu.edu

360 650 7237