FAQs Polymer Materials Engineering

Frequently Asked Questions

Our department hosts an annual Open House and Student Showcase every spring where Seniors present their research to industry partners and the campus community. We also have a “Fall Family Open House” where labs are open and students and faculty are giving program tours. We have an advisor who visits community colleges to do outreach and talk to prospective students. Our faculty attend conferences to present their research and collaborate with other institutions. A formal program called Discovery Days occurs most Fridays during the academic year at WWU (for high school students and community college students) for students to learn about WWU and the engineering and design programs.

Enrollment in the Polymer Materials Engineering program has been stable for the last three years. We would like to see interest grow. Currently, there is more demand for our students than we have available in our program. For example, there are more research opportunities while still at school and permanent job positions after graduation than we can currently fill.

In 2015, Washington graduated about 42 new engineering students for every 1,000 engineering jobs available in the state, making it 49th among the 50 states, according to a national survey. In civil engineering alone, there are 750 job openings in Washington each year, but only 350 degrees are produced here among all the schools that offer civil engineering, Bragg said. Link to article

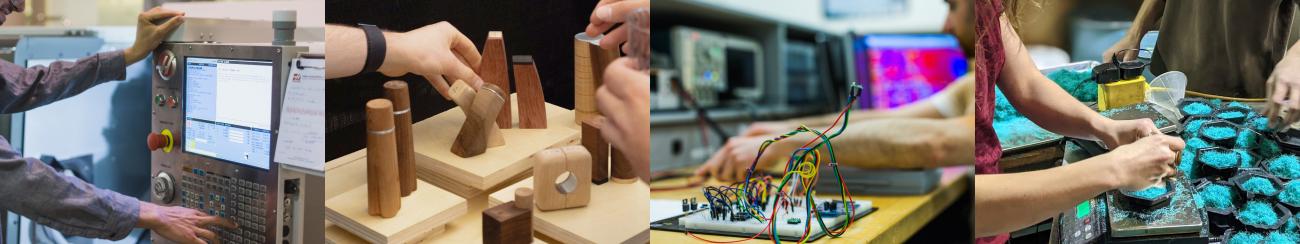

PME at WWU is primarily a manufacturing engineering curriculum focusing on plastic and composite manufacturing processes. We also have an abundance of polymer chemistry and characterization. We advance plastics manufacturing in the following ways:

- Providing industry-ready graduates from the only accredited plastics engineering program west of Kansas. Our well-equipped labs ensure graduates are proficient with production scale processing equipment, quality assurance strategies, and characterization techniques.

- Applied research collaborations with industry partners. These research projects include topics such as product design, material design, process optimization, forensics, testing and analysis.

- WWU alumni are a significant network to each other. WWU has been graduating plastics engineers since the 1970’s.

- Faculty and student research is disseminated at conferences, at training seminars for engineers, in journals and at WWU’s Engineering and Design Open House each spring.

All PME students are introduced to secondary operations early in the curriculum. Students are first introduced to assembly processes, decorating processes, and surface treatments as juniors. Through out the rest of the curriculum, assembly processes, decorating process, and surface treatments are discussed again along with relevant manufacturing processes or material properties. For example, students learn painting for the first time when they apply gel goat to a foam composite mold. Students have access to secondary operations such as powder coating, two paint booths, ultrasonic welding, hot stamping, laser etching, plasma treatment. Additionally, students can learn how secondary operations affect properties by utilizing instruments such as spectrophotometer, contact angle goniometer, adhesion strength, surface roughness (profilometer, digital and electron microscopes). Many research projects with industry partners include secondary operations. Some recent examples include:

-

Optimizing the plasma etching of a Teflon part to improve adhesion to polycarbonate for an aerospace interior part

-

Design of a dip-coating machine for consistent epoxy coating thickness on complex composite parts

-

Comparison of assembly techniques (adhesives, ultrasonic welding, fasteners) for nylon strapping on pediatric orthotics.

Graduates of our program are employed locally, regionally and across the country. Industries that recruit our graduates are from diverse fields such as aerospace, marine, automotive, defense and medical.